Global Solution Making

Accelerating Entrepreneurs and Youth Empowerment

Watch this highlight video of UN Solutions Summit 2019 at UN Headquarters in New York during UN General Assembly high-level week.

United Nations Solutions Summit

The United Nations Solutions Summit was co-created in 2015 by shift7 co-founders Megan Smith, Susan Alzner and Puneet Ahira, with the United Nations and the UN Foundation, to lift up entrepreneurs who are advancing the UN Sustainable Development Goals (SDGs). The first annual UN Solutions Summit at UN Headquarters immediately followed the adoption of the SDGs by UN Member States, demonstrating extraordinary solutions to our most complex challenges.

UN Solutions Summit identifies solution-makers from around the world through an open, participatory application and selection process, and accelerates their work by sharing it broadly, and directly connecting them with a diverse network of investors, philanthropists, industry leaders, policy-makers, and peers that are ready to help them scale their impact. UN Solutions Summit also involves in-person coaching sessions for the solution-makers with Acceleration Partners.

Learn about all of the 65 solution makers selected for UN Solutions Summit from 2015 to present here.

We shared the UN Solutions Summit methodology to the 2019 Skoll World Forum at the event “A Sharable Method for Inclusion and Impact.”

Read Forbes coverage here.

Our 2019 Acceleration Partners for the UN Solutions Summit included: H&M Foundation, Barclays, Google for Startups, Ericsson, Unreasonable Group, Safecity / RedDot Foundation, Salesforce, SDG Philanthropy Platform, Skoll Foundation, Startup Bootcamp AfriTech, Humanitarian Tracker, Vital Voices and University of Denver. Thank you to the sponsors of UN Solutions Summit 2019 for supporting travel for the solution-makers, and event production: H&M Foundation, Barclays, Google for Startups, and Ericsson.

Read about the 10 UN Solutions Summit 2019 Solution Makers and watch videos of the event here.

Nairobi, Kenya

In 2019, shift7 also co-organized UN Solutions Summit Nairobi together with UN Local 2030 and UN Foundation. It took place on June 13 during Nairobi Innovation Week, and featured 6 Solution Makers along with Acceleration Partners from the UN Resident Coordinator’s Office, UN Environment Program, UN Development Program, World Food Programme, and the Nairobi innovation ecosystem. Thank you to H&M Foundation for supporting this event.

Read a summary of the UN Solutions Summit Nairobi here and profiles of the Solutions Makers featured at this event here.

Watch videos of the full event and individual solution maker presentations here.

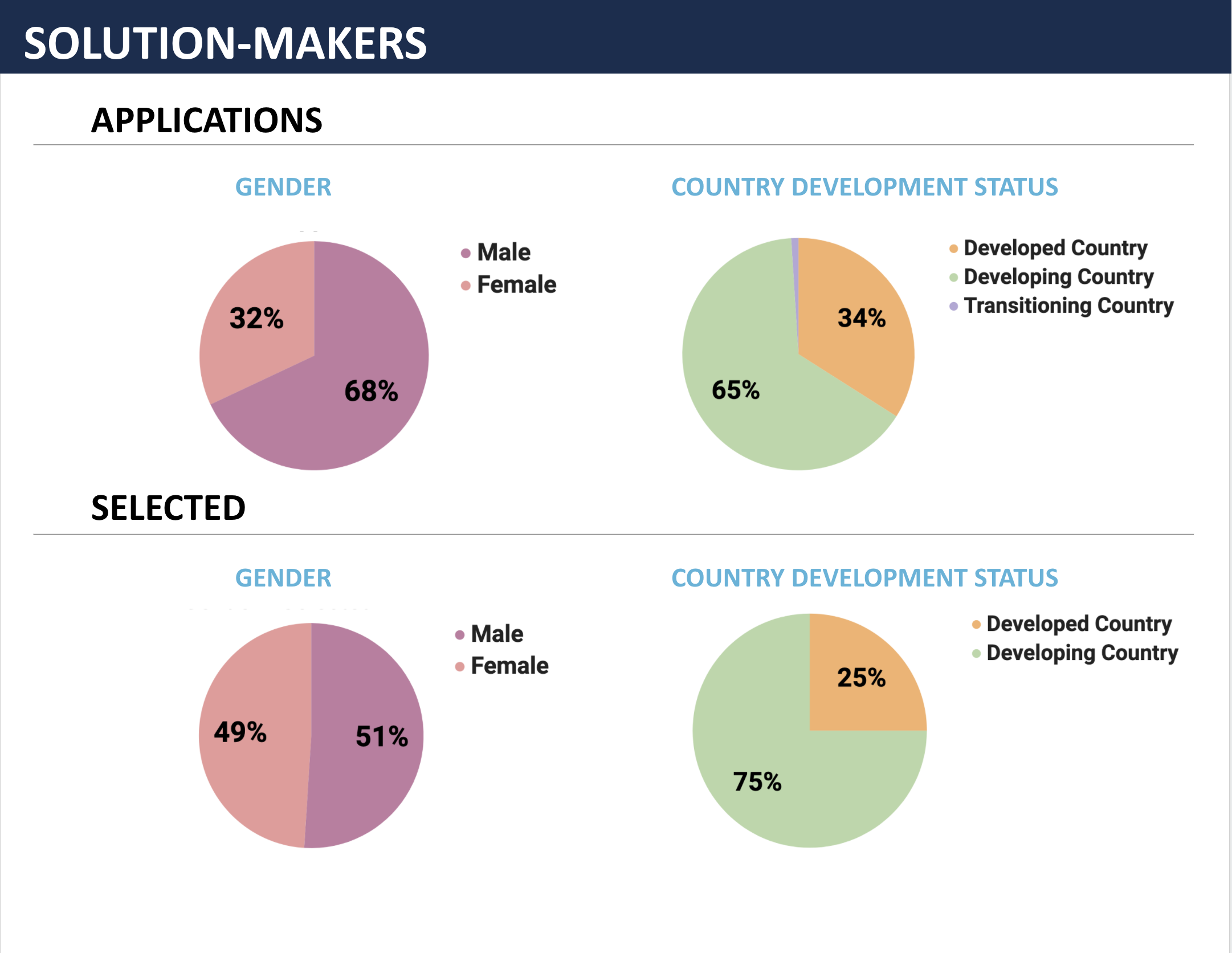

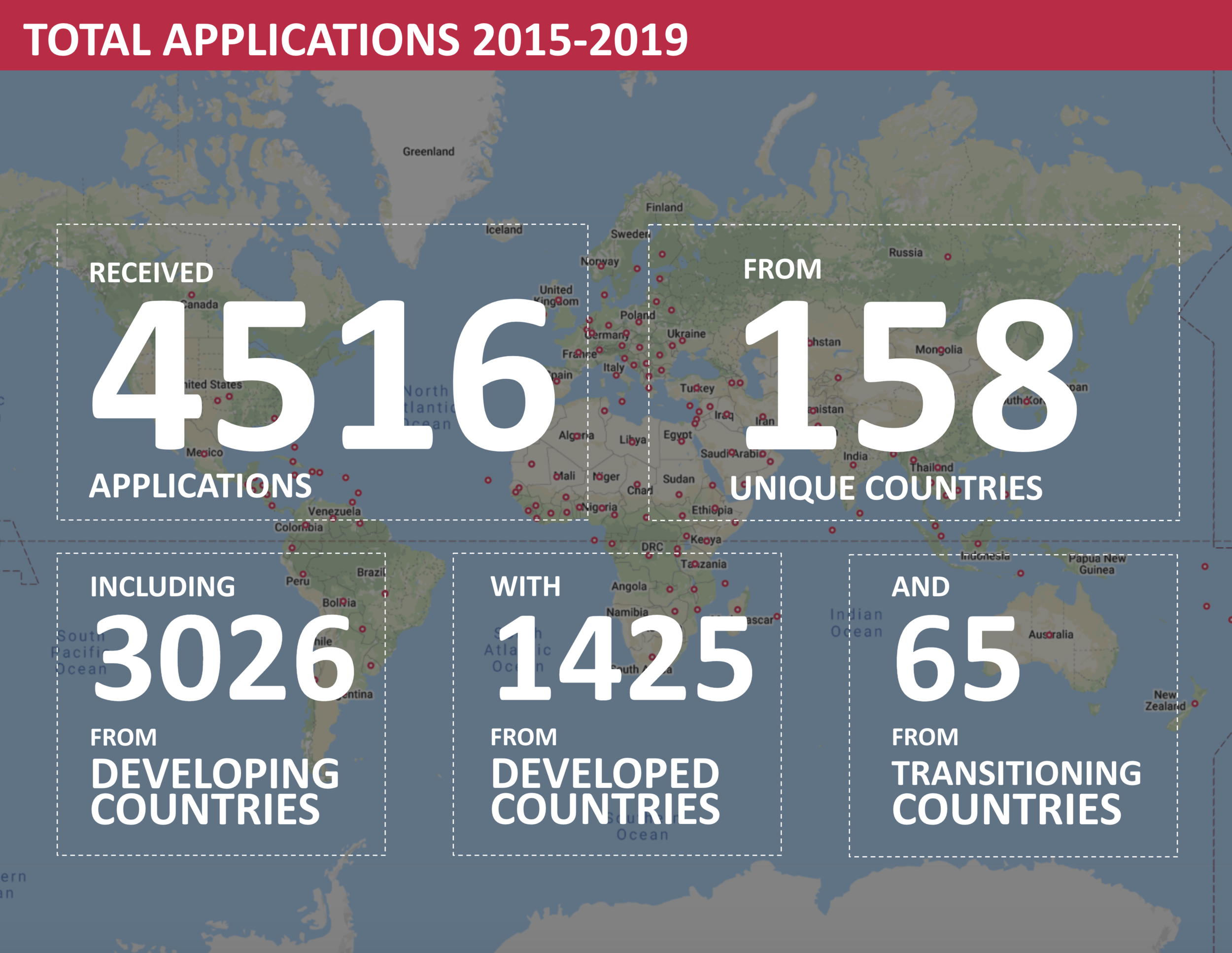

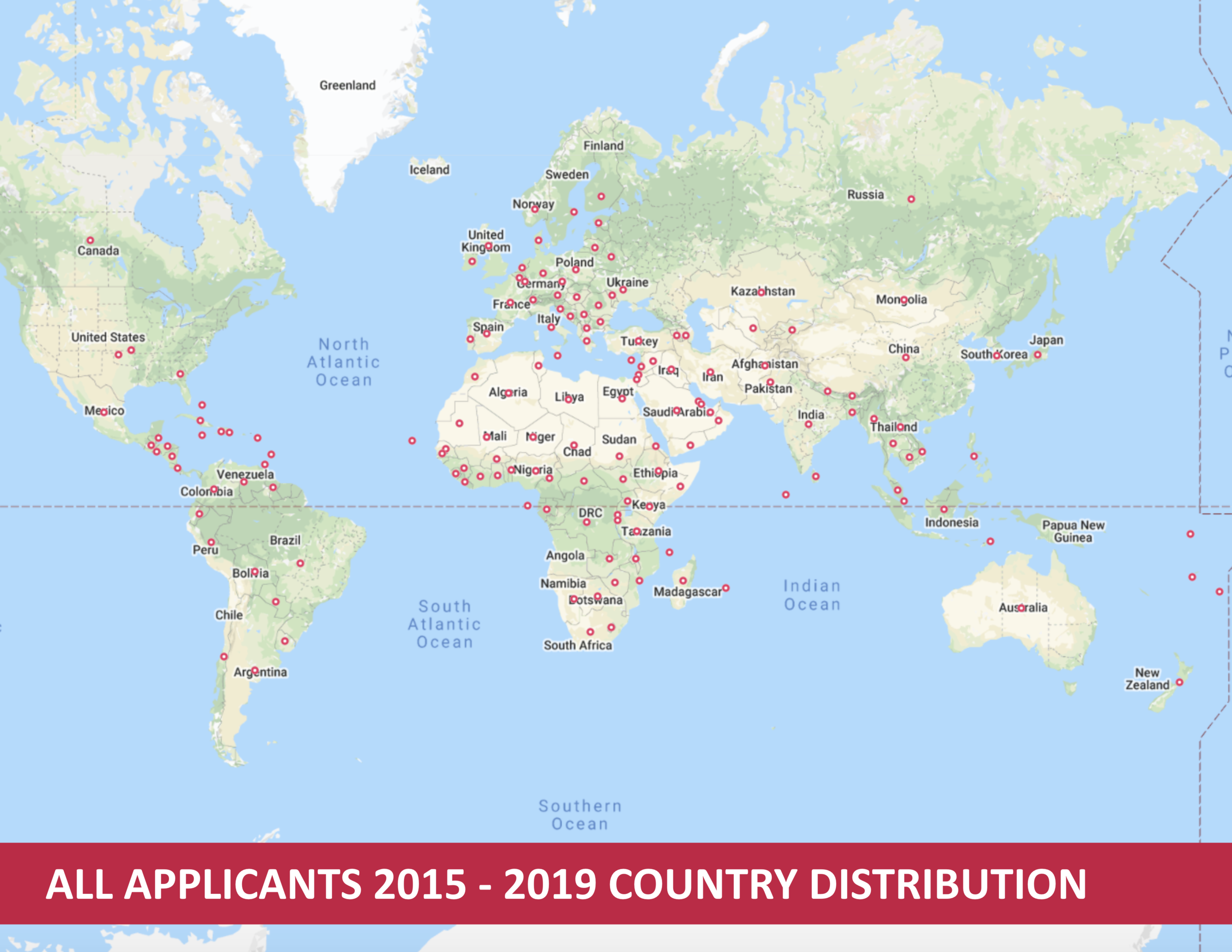

By the numbers: UN Solutions Summit at UN General Assembly 2015-2019

5 years - 4516 applications - 158 countries

55 Solution Makers selected

138 Selection Committee members

Colorado Solutions Summit participation

This method we co-created is now expanding across the UN system, and has been replicated by Colorado to further support the UN Solutions Summit solution-makers (Flight to Denver), and to accelerate Colorado-based entrepreneurs working toward SDG-related objectives (Colorado Solutions Summit).

“The credibility the platform provides is amazing and gets everyone's attention especially in a country like India. With Hend Alhinnawi (another entrepreneur selected for Solutions Summit), we are working on an Arabic version of the Safecity mobile app. With Project Xite Flight to Denver, my team chose to work on bringing Safecity to Denver. This helped us think through our projects deeper as there was a diverse group who gave us inputs to strengthen our work.”

- Elsa D’Silva, Founder and CEO of Safecity, India

Youth empowerment

As part of our work, shift7 continually reaches out to youth organizations -- working to interconnect programs and evangelize their exceptional work. For example, we help the Chief Science Officers (CSOs) team to grow in more regions. In 2016, some of our leadership co-catalyzed the Computer Science for All (CS for All) movement when in government -- today we stay closely engaged to support the core CS for All teams. Here’s our Conversation with Cartoon Network at the CS for All Summit about use of media to engage more youth in tech and inspire creative confidence. We evangelize active-STEM, such as Science Fair experiences, and support incredible story telling like Inventing Tomorrow, a film about how effective Science Fair experiences can be. Plus, we share great models that are really working like XQsuperschools, FIRST Robotics, Black Girls Code and Girls Who Code.